This new design was different—so novel, in fact, that it would not only help to solve a problem that had long plagued printers, but would one day launch a company and create an entire industry essential to global productivity and personal comfort.

The problem began with paper. In the spring of 1902, consulting engineer Walter Timmis visited the Manhattan office of J. Irvine Lyle, the head of Buffalo Forge’s sales activities in New York. Timmis’ client, Sackett & Wilhelms, found that humidity at its Brooklyn plant wreaked havoc with the color register of its fine, multicolor printing. Ink, applied one color at a time, would misalign with the expansion and contraction of the paper stock. This caused poor quality, scrap waste and lost production days, Timmis said. Judge magazine happened to be one of the important clients whose production schedule was at risk. Timmis had some ideas about how to approach the problem but would need help. Was Buffalo Forge interested?

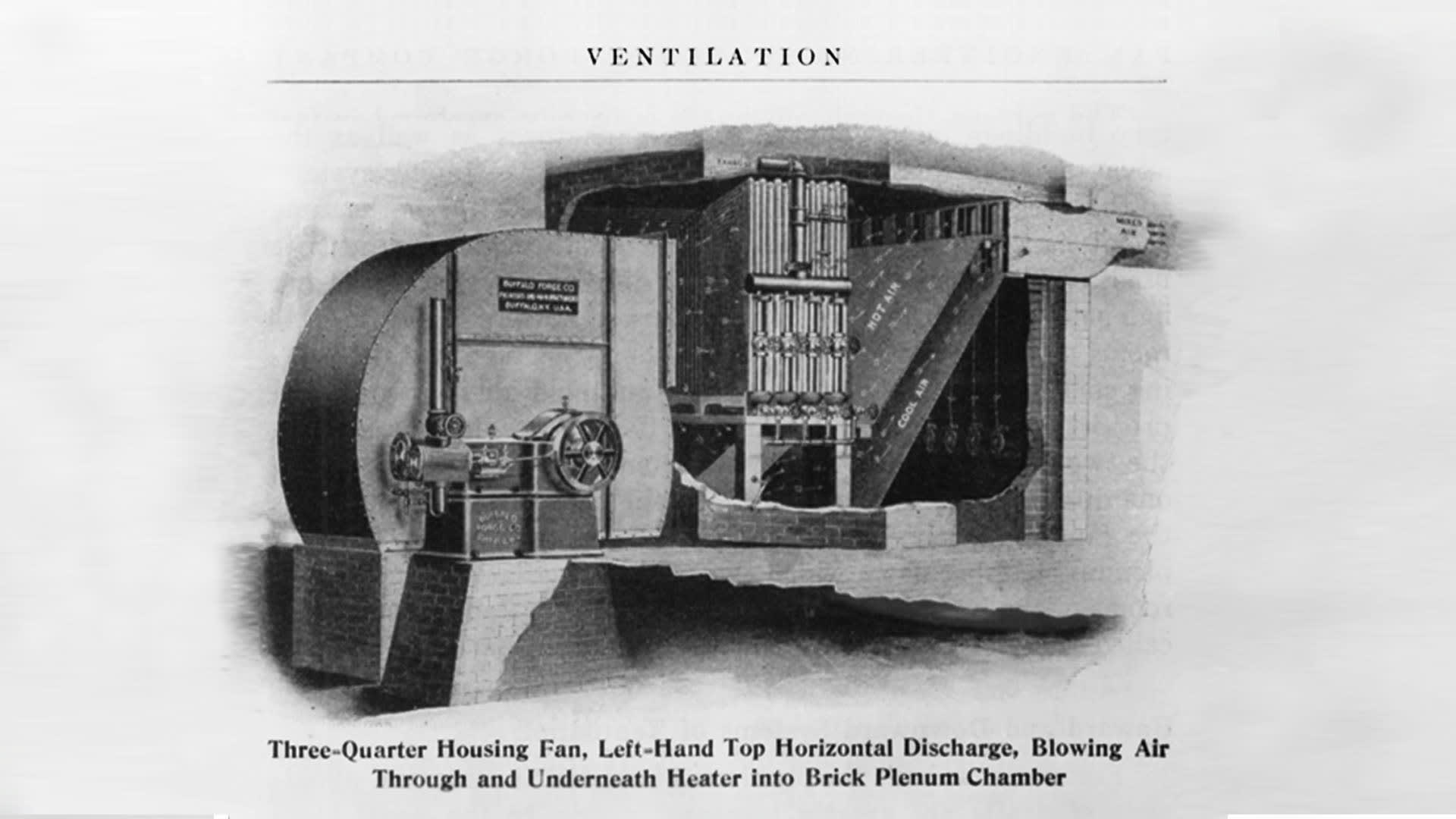

One of Lyle’s great skills was his ability to assess new business opportunities, and he grasped this one immediately. He knew that engineers had long been able to heat, cool and humidify air. Sometimes, as a result of cooling, they had also been able to reduce humidity. But precise control of humidity in a manufacturing environment—that was something entirely new. Lyle also had an innate ability for sizing up people. In this case, he believed he knew the engineer who could tackle this problem, a recent Cornell University graduate who had already impressed many people at Buffalo Forge. So, Lyle accepted Timmis’ challenge and sent the problem to Willis Carrier, the first step in a long and prosperous collaboration.

Energized by the puzzle, Carrier immediately grasped the issues and began his investigation by means of rigorous testing and intensive data-gathering, hallmarks of his long career. His first test was recommended by Timmis and involved a roller towel with loosely woven burlap saturated with a solution of calcium chloride brine. While the apparatus removed humidity, it added heat, salt and odor to the air, none being acceptable in the printing process.